I finally got around to ordering the cooler for the galley area. I dimensioned the space around a Coleman Steel Belted cooler which cost approximately $130. I found a similar one for approximately half the price on Amazon and it fit perfectly.

|

| Cooler in Galley Area Drawer |

|

| Cooler Drawer Extended |

|

| Cabinet Clearance Passenger Side |

|

| Cooler Cabinet Clearance Driver Side |

|

| Overall View |

I needed to make the receiver tongue for the trailer; I originally was going to get a multi-directional receiver hitch but but I didn't want to spend $250 for it at this time, so I moved forward with the $30 option of purchasing 28 inch long 2" x 2" x 1/4" thick square tubing and a 2" ball coupler. This will work just fine for most uses until we really want to do some serious off-roading; I can just purchase or make that attachment later. I made my coupler tongue just long enough to so if I ever get into a jack-knife situation or tight turning condition, the bumper of the car will hit the tongue in lieu of the battery box.

|

| Multi-directional Off Road Coupler +/- $250 |

|

| 28 Inch Long Square Tubing with Holes Drilled |

|

| Tongue Coupler Fit-up |

|

| Tongue Coupler Fit-up - View 2 |

|

| 2 Inch Ball Coupler Attached |

I will disassemble the coupler, paint the tongue black, get some chains installed and this part is complete.

I need a relatively accurate cutout for the solar cable entrance through the aluminum sheet, so to get an accurate dimension I string lined across the front sheet to get the offset distance from the front sheet to the cable entrance. I also need to take out some of the aluminum at the star gazer opening so I can clamp the aluminum sheet through the curve.

|

| String Line to Measure Cutouts for Next Aluminum Sheet |

|

| Measuring for Solar Panel Electrical Connection |

|

| Taped off Area for Cutouts |

I want the top center sheet above to overlap the front and back sheet to address the natural flow of water off the roof, so I trimmed the back sheet to length and installed it before the top center sheet.

|

| Trimming Top Back Sheet to Length with Router |

|

| Top Back Sheet Installed |

The back top sheet ends just before the vent opening so the riveted seam will not conflict with the vent lip, and I should get a good seal.

|

| Back Top Sheet Ends Just Before Vent |

|

| Preparing for the Last Top Sheet |

|

| Top Sheet Installed and Solar Panel Leads Run Through |

I knew that cutting the top sheets to a 5 ft width would present it's problems for alignment, but I couldn't get aluminum sheets longer than 10 ft (cut in half) nor did I want to waste 3 ft off the edges by using a 4 x 8 ft sheet of aluminum. I will thoroughly caulk under the edge trim, and the edge trim will fully cover the offset.

|

| Slight Drift of Top Sheet (Drivers Side) |

|

| Drift of Top Sheet (Passenger Side). Will Trim with Router. |

|

| Trim will more than cover the offset |

|

| Solar Panel Cables Through Roof |

|

| Caulking under Panel Joints Before Riveting |

|

| Added Caulk to Each Rivet Hole before Riveting |

|

| Excess Caulk Protruding from Seam |

|

| Joint Rolled after Caulking |

|

| Rivet Layout - 3 Inches On Center |

|

| 1/8 Inch Rivets being Installed |

Once I complete installing all the rivets, I will caulk the heads so moisture cannot penetrate through the shaft area of the rivet.

|

| Roof Rivets Complete |

|

| Another View of Roof Rivets |

The sheet layout landed a seam at the star gazer window location. Although there will be a ridge at the interface of the window and the aluminum, I figure the window can hold the aluminum in place verses having a full width seam somewhere else on the trailer. I will just need to assure I have sufficient caulking around the window frame.

Since the seam landed in the 2 ft radius curve, the sheet didn't want to lay flat, so I clamped and held the seam in place while I riveted the area in the curve.

|

| Seam Bowing Up in the 2 ft Radius Area |

|

| Front Edge Seam by Star Gazer Window |

|

| Rivet Layout at Star Gazer Window |

|

| Avoid Rivets under Trim |

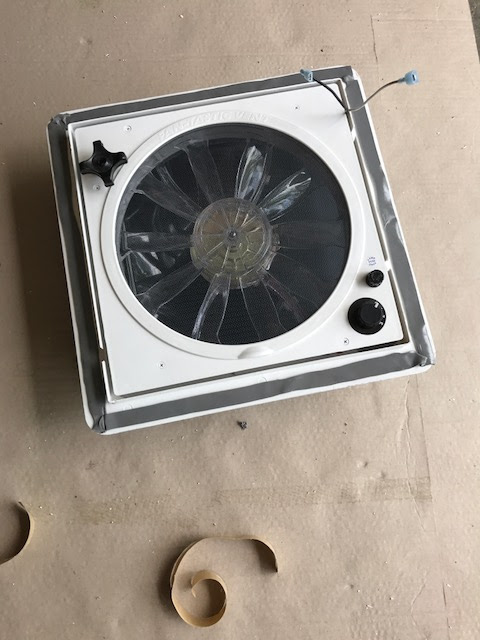

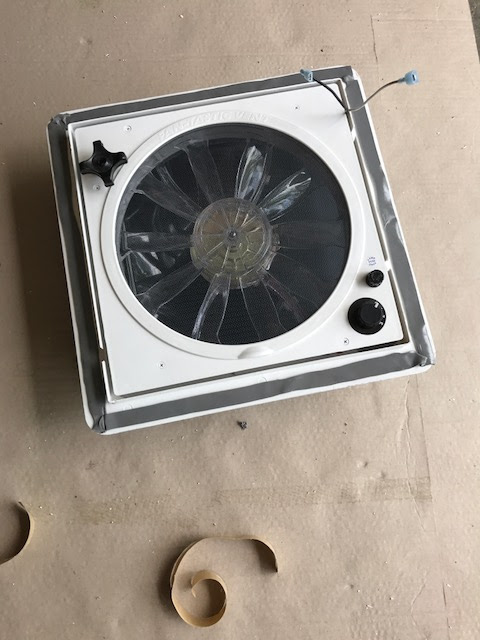

I trimmed out the excess aluminum at the vent area and the solar panel cable entrance to finish the installs on the roof. I used a butyl rubber sealant around the perimeter where the screws will be placed and this butyl will seal up around the screws.

|

| Butyl Sealant at Roof Vent |

|

| Another View |

|

| Install Complete |

|

| Vent Trim Ring Installed |

Interior on the trailer is complete with the exception of installing shelves in the sleeping quarters cabinets, installing 1 trim piece and the TV; time to get the trim on and complete the galley hatch and battery box.

No comments:

Post a Comment